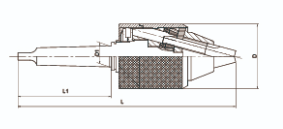

| Mohlala | Sebaka sa ho koala | sebaka sa ho phunya | Sebaka sa ho tlanya | D | D1 | L1 | L | |||||||

| mm | in | mm | in | mm | in | mm | in | mm | in | mm | in | mm | in | |

| J0113M-MT2 | 1-13 | 0.039-0.512 | 1-22 | 0.039-0.866 | M3-M16 | 1/16-5/8 | 50 | 1.968 | 17.78 | 0.7 | 78.5 | 3.09 | 178 | 7.008 |

| J0113-MT2 | 1-13 | 0.039-0.512 | 1-30 | 0.039-1.181 | M3-M24 | 1/16-7/8 | 55 | 2.165 | 17.78 | 0.7 | 78.5 | 3.09 | 184.5 | 7.264 |

| J0116-MT2 | 1-16 | 0.039-0.63 | 1-30 | 0.039-1.181 | M3-M24 | 1/16-7/8 | 63 | 2.48 | 17.78 | 0.7 | 78.5 | 3.09 | 198.5 | 7.815 |

| J0116-MT3 | 1-16 | 0.039-0.63 | 1-30 | 0.039-1.181 | M3-M24 | 1/16-7/8 | 63 | 2.48 | 23.825 | 0.938 | 98 | 3.858 | 218 | 8.583 |

ho tlanya le ho phunya li-chucks tse ithatafatsang ka li-shank tse kopantsoeng ke lisebelisoa tsa bohlokoa tse sebelisoang ts'ebetsong ea machining.E 'ngoe ea liqapi tse tummeng ka ho fetisisa tsa li-shanks tse kopantsoeng ke Morse taper e nang le tang, e etselitsoeng ho fana ka khokahanyo e sireletsehileng le e tsitsitseng pakeng tsa chuck le mochine oa ho ohla.

Morse taper e nang le moralo oa tang oa ho tlanya le ho phunya li-chucks tse ithatafatsang ka li-shank tse kopantsoeng li thehiloe mokhoeng o tloaelehileng oa ho boloka lisebelisoa ka har'a mochini o ohlang.Morse taper e fana ka mokhoa o ka tšeptjoang le o nepahetseng oa ho tsamaisa lisebelisoa, ha tang e tiisa hore chuck e lula e tiile nakong ea tšebeliso.

E 'ngoe ea melemo ea mantlha ea ho tlanya le ho phunya li-chucks tse ithatafatsang ka li-shank tse kopaneng tse sebelisang taper ea Morse e nang le moralo oa tang ke ho feto-fetoha ha tsona.Li-chucks tsena li fumaneha ka mefuta e fapaneng ea boholo le mekhoa ho lumellana le litlhoko tse fapaneng tsa machining.Li ka boela tsa sebelisoa le mefuta e fapaneng ea lisebelisoa tse fapaneng, ho kenyelletsa le likotoana tsa ho cheka le lipompo.

Molemo o mong oa taper ea Morse e nang le moralo oa tang ke boiketlo ba eona ba ho e sebelisa.Shank e kopantsoeng le chuck li felisa tlhokahalo ea likarolo tse arohaneng, tse ka bolokang nako le boiteko nakong ea liphetoho tsa lisebelisoa.Ho feta moo, moralo o kopaneng oa li-chucks tsena o etsa hore ho be bonolo ho li boloka le ho li tsamaisa.

ho tlanya le ho phunya li-chucks tse ithatafatsang ka li-shank tse kopantsoeng tse sebelisang Morse taper e nang le moralo oa tang hangata li entsoe ka thepa ea boleng bo holimo, joalo ka tšepe e thata kapa carbide.Sena se tiisa hore li tšoarella ka nako e telele 'me li khona ho mamella mathata a ts'ebetso ea mochini o boima.Li boetse li hloka tlhokomelo e fokolang, e leng se etsang hore e be tharollo e theko e tlaase bakeng sa machinist.

E le ho etsa bonnete ba hore ts'ebetso e ka tšeptjoang le e tsitsitseng, ke habohlokoa ho latela mekhoa e nepahetseng ea ho kenya le ho lokisa ha u sebelisa "chuck" ea ho itlama le ho phunya ka shank e kopantsoeng e sebelisang Morse taper e nang le moralo oa tang.Hangata sena se kenyelletsa ho kenya sesebelisoa ka hloko ka har'a chuck le ho tiisa mehlahare ea chuck ho tiisa sesebelisoa sebakeng.Ho bohlokoa hape ho lula u lekola chuck hore na e senyehile kapa e senyehile le ho khutlisa likarolo life kapa life tse tsofetseng kapa tse senyehileng ha ho hlokahala.

Ka bokhutšoanyane, ho tlanya le ho phunya li-chucks tse ithatafatsang ka li-shank tse kopantsoeng ka ho sebelisa Morse taper e nang le moralo oa tang li na le lisebelisoa tse ngata, tse bonolo ho li sebelisa, le tse tšoarellang tse hlokahalang bakeng sa ts'ebetso ea mochine.Ka ho khetha shank chuck e nepahetseng e kopantsoeng bakeng sa litlhoko tsa hau tse khethehileng tsa mochini le ho latela mekhoa e nepahetseng ea ho kenya le ho e lokisa, o ka etsa bonnete ba hore ts'ebetso e ka tšeptjoang le e tsitsitseng bakeng sa lilemo tse tlang.