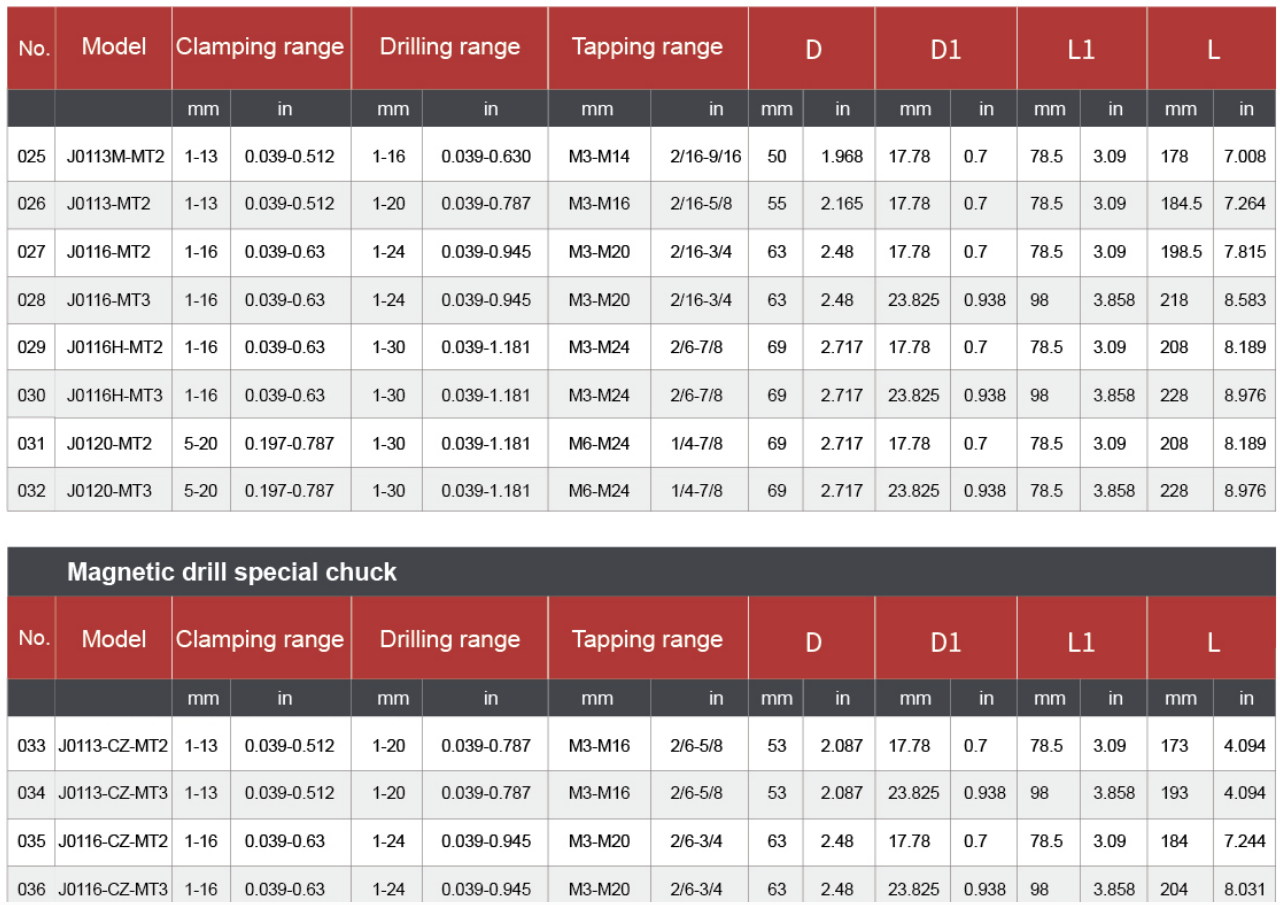

| mohlala | Sebaka sa ho koala | Sebaka sa ho cheka | Sebaka sa ho tlanya | D | D | L1 | L | |||||||

| mm | in | mm | in | mm | in | mm | in | mm | in | mm | in | mm | in | |

| J0113M-C20 | 1-13 | 0.039-0.512 | 1-22 | 0.039-0.866 | M3-M16 | 1/16-5/8 | 50 | 1.968 | 20 | 0.787 | 60 | 2.362 | 159 | 6.26 |

| J0113-C20 | 1-13 | 0.039-0.512 | 1-30 | 0.039-1.181 | M3-M24 | 1/16-7/8 | 55 | 2.165 | 20 | 0.787 | 60 | 2.362 | 166 | 6.535 |

| J0116-C20 | 1-16 | 0.039-0.63 | 1-30 | 0.039-1.181 | M3-M24 | 1/16-7/8 | 63 | 2.48 | 20 | 0.787 | 60 | 2.362 | 180 | 7.887 |

| J0116-C25 | 1-16 | 0.039-0.63 | 1-30 | 0.039-1.181 | M3-M24 | 1/16-7/8 | 63 | 2.48 | 25 | 0.984 | 80 | 3.15 | 200 | 7.874 |

Taper mount tapping le ho cheka li-chuck tse ithatafatsang ke lisebelisoa tse ikhethileng tse sebelisetsoang ho ts'oara le ho boloka likotoana tsa ho cheka le lipompo nakong ea ts'ebetso ea mochini.Li-chucks tsena ke likarolo tsa bohlokoa tsa ho seta mochini ofe kapa ofe 'me li sebelisoa haholo liindastering tse fapaneng, ho kenyeletsoa sefofane, likoloi le tlhahiso.

Moralo oa taper mount chuck o ipapisitse le sistimi ea Morse taper, e leng mokhoa o tloaelehileng oa ho boloka lisebelisoa mochining oa spindle.Li-chucks tsa Taper Mount li na le taper e tona e etselitsoeng ho lekana hantle ka har'a taper e ts'oanang ea basali mochining oa spindle.Sena se fana ka khokahanyo e sireletsehileng le e tsitsitseng e netefatsang ho nepahala ha lisebelisoa le ho fokotsa ho fela ha lisebelisoa.

E 'ngoe ea melemo ea bohlokoa ea taper mount chucks ke ho feto-fetoha ha tsona.Li-chucks tsena li ka tšoara boholo ba lisebelisoa le libopeho tse fapaneng, ho kenyelletsa le likotoana tsa ho cheka, lipompo, li-reamer le li-mill tsa ho qetela.Sena se li etsa hore li tšoanelehe bakeng sa lisebelisoa tse fapaneng tsa machining, ho tloha ho ho cheka le ho tlanya ho isa ho tse tenang le ho sila.

Li-chuck tsa Taper Mount li tumme ka ho tšoarella ha tsona le ho ts'epahala ho kenyelletsa ho ikamahanya le maemo le mokhoa o bonolo oa ts'ebeliso.Ho mamella litlhoko tsa ts'ebetso ea machining e boima, li-chucks tsena hangata li hahiloe ka thepa ea boleng bo holimo joalo ka tšepe e thata kapa carbide.Li boetse li hloka tlhokomelo e fokolang le ho hlokomeloa ho boloka ts'ebetso e tšoarellang nako e telele.

E le ho thibela ho felloa ke lisebelisoa le ho theola monyetla oa ho senyeha ha li-chuck kapa mochini oa spindle ha u ntse u sebelisa taper mount chuck, ho bohlokoa ho netefatsa ho kenya lisebelisoa le ho tsamaisana hantle.E le ho etsa sena, hangata sesebelisoa se kenngoa ka har'a chuck 'me mehlahare ea chuck e tiisitsoe ho tšoara sesebelisoa sebakeng seo.Ho feta moo, ho bohlokoa ho lula u lekola chuck hore na e senyehile kapa e senyehile, 'me u nke sebaka sa lisebelisoa tse tsofetseng kapa tse senyehileng ha ho hlokahala.

E le ho thibela ho felloa ke lisebelisoa le ho theola monyetla oa ho senyeha ha li-chuck kapa mochini oa spindle ha u ntse u sebelisa taper mount chuck, ho bohlokoa ho netefatsa ho kenya lisebelisoa le ho tsamaisana hantle.E le ho etsa sena, hangata sesebelisoa se kenngoa ka har'a chuck 'me mehlahare ea chuck e tiisitsoe ho tšoara sesebelisoa sebakeng seo.Ntle le moo, ho bohlokoa ho lula u lekola chuck hore na e senyehile kapa e senyehile, ebe u kenya likarolo tse tsofetseng kapa tse senyehileng ha ho hlokahala.

Ka kakaretso, ho ithatafatsa taper mount tapping le li-chucks tsa ho phunya ke lisebelisoa tse hlokahalang bakeng sa ts'ebetso efe kapa efe ea machining.Ho ikamahanya le maemo le ho tšoarella ha bona ho etsa hore ba phethehe bakeng sa mefuta e fapaneng ea likopo, 'me ba fana ka khokahanyo e sireletsehileng le e ka tšeptjoang bakeng sa lisebelisoa tse ngata.Ka ho khetha taper mount chuck e nepahetseng bakeng sa litlhoko tsa hau tse khethehileng tsa machining le ho latela mekhoa e nepahetseng ea ho kenya le ho lokisa, u ka khona. netefatsa ts'ebetso e tšepahalang le e tsitsitseng bakeng sa lilemo tse tlang.